Call us on

+44 (0)1268 777871Proteus Pro-Felt® Ultima Plus – Durable, Plastomeric Torch-On Membrane

The Proteus Pro-Felt® Ultima Plus system, BBA certified to deliver a service life in excess of 30 years, is a plastomeric modified bitumen solution, designed to provide long-lasting protection for flat or pitched roofs with limited access. Whether specified as a direct waterproofing overlay or as part of the proven Proteus Waterproofing built-up roof system, Ultima Plus delivers exceptional durability and dimensional stability.

Attenu8®

Attenu8®: A new standard in Blue Roof performance

As rainfall intensifies and planning demands grow, today’s buildings need smarter, compliant solutions. Proteus Attenu8® is a fully integrated attenuated blue roof waterproofing system that meets the toughest regulatory, thermal and SuDS requirements – all in one coordinated package.

Proteus Pro-Felt® Endura SA AVCL

Proteus Pro-Felt® Endura SA AVCL is a cold-applied vapour control layer. It is a self-adhesive bituminous membrane that features a top layer saturated and coated SBS modified bitumen to provide protection against moisture and vapour.

Proteus Pro-Felt® Endura AVCL

Proteus Pro-Felt® Endura AVCL is a torch-applied vapour control layer. It is a bituminous membrane that features a top layer saturated and coated with SBS modified bitumen to protect against moisture. It includes an aluminium barrier and 60g/m² glass fleece reinforcement.

Proteus Pro-Felt® Endura SA Underlay Sanded

Proteus Pro-Felt® Endura SA Underlay Sanded is a self-adhesive bituminous underlay is a waterproofing solution for most cold-applied roofing applications.

Proteus Pro-Felt® Endura Mineral Anthracite

Proteus Pro-Felt® Endura Mineral Anthracite is a solution for torch-applied roofing needs. This bituminous cap sheet is designed to provide reliable performance.

Proteus Pro-Felt® Endura SA Mineral Anthracite

Proteus Pro-Felt® Endura SA Mineral Anthracite – The solution for a wide range of cold-applied roofing needs. This self-adhesive bituminous cap sheet is specifically designed to provide durability.

Proteus Pro-Felt® Endura AIRdhesive,

Proteus Pro-Felt® Endura AIRdhesive, delivers single-ply roofing with the benefit of elastomeric felt. This system consists of a single layer of bituminous membrane, saturated and coated with SBS (Styrene-Butadiene-Styrene) modified bitumen, with a host of additional features.

Proteus Pro-Felt® Endura – High-Performance Warm Roof System

Designed for safety, reliability and certified to deliver a service life of at least 35 years, the Proteus Pro-Felt® Endura system delivers a complete warm roof solution that meets the demands of modern roofing professionals. Proven for use on a wide range of substrates, it combines self-adhesive and torch-on technologies to provide maximum design flexibility without compromising on durability.

Proteus Pro-Cold®

Proteus Pro-Cold® is a seamless and cold-applied waterproofing membrane for flat roofs, pitched roofs and a waterproofing coating to Proteus’ Built-Up Roof systems.

Trims

Proteus Waterproofing stocks a range of trims.

Pro-CEC

Pro-CEC is the fast cure solution to cut edge corrosion commonly found on metal cladding at the edges of the sheet. As the metal is left exposed and corrodes, the simple application of Pro-CEC will prevent further peel back of the protective coating and eventual panel replacement.

Pro-Cryl®

Pro-Cryl® is a multi-purpose roof coating for extending the service life of a wide range of flat and pitched roofing systems

Deckmaster

Deckmaster provides seamless waterproofing for roofs, basements, car parks and intermediate decks while protecting them from carbon dioxide and chloride ingress.

Cold Melt® DPM Primer

Cold Melt® DPM Primer is designed for use as a coating over cementitious surfaces which possess high levels of residual moisture, or have not been protected by an underlying moisture barrier.

Proteus Pro-Therm

Our in house technical design team can overcome challenging project criteria with innovative design solutions and hybrid options.

Pro-Living®

Proteus Waterproofing offers a range of green, brown and blue roofs. Pro-Living® roofs can provide ecological benefits, offering an effective and practical use of space.

Pro-BW® Plus

Pro-BW® Plus is a liquid-applied, rapid curing protective coating that provides a colourfast, UV stable and skid-inhibiting surface for balconies and walkways.

Proteus Hot Melt®

Exploring the Proteus Hot Melt® Waterproofing System: Durable Solutions for Contemporary Roofing Needs

Cold Melt®

Cold Melt® is a two-part elastomeric polyurethane membrane that delivers seamless leak protection for protected roofs, including zero fall designs. Incorporating recycled rubber crumb and castor oil, this BBA-certified system (Certificate 23/6654) provides durable waterproofing when installed and maintained as specified.

Proven Waterproofing Performance

Suitable for use in warm roof build-ups or as a standalone waterproofing membrane, Proteus Pro-Felt® Ultima Plus offers a robust solution for both new-build and refurbishment projects. Manufactured with distilled bitumen and elasto-plastomeric polymers (APP), the system delivers consistent performance, flexibility and long-term protection.

The system includes the Ultima Plus Mineral Capsheet, a single-strand composite polyester reinforcement, which offers excellent mechanical strength and dimensional stability. When combined with Proteus Pro-Felt® SA Underlay or the Ultima Plus Sanded Underlay, it forms into a reliable, multi-layered waterproofing system.

Specialist Anti-Root Protection

Proteus Pro-Felt® Ultima Plus is also suitable for green roof applications or areas where planting is required, when using the Ultima Plus Anti-Root Capsheet, which provides more targeted protection. Designed with special additives and reinforced non-woven polyester, it resists root penetration and aggressive chemicals such as fertilisers and herbicides, without compromising the life and health of vegetation. The anti-root properties are permanent and are unaffected by weathering, water, or torch-on application.

Key Features & Certifications

- Fire tested - Achieves Broof(t4) performance.

- BBA Certified - Independently verified for a service life of 30+ years under normal conditions.

- Long-term guarantee - Backed by the 25-year Proteus Waterproofing Guarantee.

- Durability - Provides a resilient waterproof covering with proven dimensional stability.

- Certified quality - Manufactured to ISO 9001, 14001 and 45001 standards.

Why Choose Proteus Pro-Felt® Ultima Plus?

- High mechanical performance with APP-modified technology.

- Flexible specification for warm roofs, overlays, or as part of a built-up system.

- Root-resistant options for intensive or extensive green roof applications.

- Proven longevity with independent BBA certification and system guarantees.

Proteus Pro-Felt® Ultima Plus combines proven APP-modified bitumen technology with system flexibility and long-term certification, making it the ideal choice for architects, contractors and specifiers looking for a reliable, BBA-approved waterproofing solution.

A one-stop shop for blue roof design and delivery

Specify Attenu8® and you benefit from a complete solution - from first enquiry to final installation. A cradle to grave service which covers a wide range of different waterproofing applications including Green Roofs and Inverted Felt Roofs. We also offer a choice of membranes including Pro-BW® Plus waterproofing, Proteus Cold Melt®and Proteus Hot Melt. Attenu8® further includes:

- Total system design, bespoke to each project-specific requirement.

- Dedicated technical support from our in-house specialist team.

- Installation exclusively via approved contractors.

- End-to-end service from early-stage planning to final commissioning and beyond

- A single point of specification and insured design responsibility.

- Comprehensive insurance-backed guarantees covering every system component.

This system has the ability to deliver integrated 'safe-seal' lap technology, to ensure the side-laps are sealed, creating a suitable vapour barrier. The glass fibre and aluminium composite reinforcement also provide additional strength.

The underside of the membrane is equipped with a separating foil to ensure reliable adhesion. The top side is finished with quartz sand, which enhances adhesion with subsequent thermal insulation.

Designed as a vapour barrier, Proteus Pro-Felt® Endura SA AVCL is suitable for cold-applied roofing systems. It can be applied to a wide range of substrates, including plywood, metal, and concrete decks, with the use of a suitable primer as required. This versatility allows for integration into various roofing applications.

The presence of quartz sand on the top side ensures firm adhesion with subsequent thermal insulation. Additionally, joints and overlaps can be sealed through (hot air) welding where necessary, to ensure a secure installation.

The vapour control layer offers strength and durability, while the underside of the membrane is equipped with a thermofusible polyethylene film to assist with installation and torch application. The top surface is finished with quartz sand, providing traction and walkability.

Designed as a vapour barrier membrane, Proteus Pro-Felt® Endura AVCL is suitable for torch-on roofing systems. It can be applied to a wide range of non-combustible substrates, including metal and concrete decks, subject to the use of a suitable primer as required.

With its aluminium reinforcement, the system is also resistant to alkali and corrosion.

Pro-Felt® Endura SA Underlay Sanded features a top layer saturated and coated with SBS modified bitumen to ensure protection against the elements. The system features a 200g/m² pure glass fibre reinforcement for strength and durability.

The underside of the underlay is equipped with a single layer removable film to assist with application. The top surface is finished with a sanded texture, providing traction and walkability.

Designed as an underlay membrane, Proteus Pro-Felt® Endura SA Underlay Sanded is recommended for use with the Proteus Torch-Safe System. It is compatible with a wide range of substrates and thermal roof insulation boards and can also be used with all common bituminous vapour control layers and cap sheets.

The System features a top layer saturated and coated with high-quality SBS modified bitumen, ensuring superior protection against the elements. The product also incorporates a strong 180g/m² polyester fleece reinforcement, providing excellent strength and durability.

For added convenience and ease of installation, the underside of the cap sheet is equipped with a thermofusible polyethylene film. This feature ensures efficient and reliable torch application, saving time on site. The distinctive slate surfaced finish also ensures that every project will look good once completed. The System incorporates a special graphite additive within the membrane, enhancing its ability to withstand fire.

Designed as a high-performance cap sheet, the Pro-Felt® Endura Mineral Anthracite is perfect for a variety of Proteus Waterproofing built-up roofing systems, whether it's a Torch-Safe or full Torch-On specification. The System is also compatible with all common bituminous underlay membranes.

The System features a top layer saturated and coated with high-quality SBS modified bitumen, ensuring superior protection against the elements. The membrane also features a robust 280g/m² polyester/glass composite reinforcement, guaranteeing exceptional strength and longevity.

What sets this product apart is the integrated 'safe-seal' lap technology, which enables easy, secure, and efficient sealing of side-laps.

To further enhance its capabilities, the upper layer of the membrane is shielded with slate mineral, providing additional protection and aesthetic appeal. The bottom layer is coated with a self-adhesive compound, ensuring convenient installation. This is covered with a removable film for added convenience and ease of application.

Proteus Pro-Felt® Endura SA Mineral Anthracite also delivers excellent fire performance thanks to a special graphite additive within the membrane. This enhances its ability to withstand fire.

Designed as a premium cap sheet, the Pro-Felt® Endura SA Mineral Anthracite is perfect for cold-applied roofing systems. It seamlessly integrates with Proteus' self-adhesive or torch-safe specifications and is compatible with Proteus Pro-Felt® Endura SA Underlay Sanded and Pro-Prime® SA, to provide a comprehensive roofing solution.

The Proteus Pro-Felt® Endura AIRdhesive incorporates a high-quality polyester reinforcement, ensuring maximum strength and reliability. Its upper surface is finished with a mineral coating, providing an attractive and robust layer of protection. On the underside, is a robust fleece finish, adding an extra dimension of quality and strength.

Proteus Pro-Felt® Endura AIRdhesive can be easily bonded using the Proteus Pro-Membrane Adhesive, mechanically fixed to suitable substrates or where suitable, fully torch applied to provide installers with the freedom to choose the method that suits the specific project requirements. For added convenience, this membrane can be specified as a completely flame-free waterproofing solution, ensuring a safe and efficient installation process. Furthermore, it serves as a fast-track method for overlaying existing roof coverings, saving time and costs.

Proteus Pro-Felt® Endura AIRdhesive delivers exceptional performance during installation, but its advanced formulation also guarantees outstanding functionality in a variety of conditions. It exhibits excellent flexibility at low temperatures, allowing it to withstand even the harshest climates. Additionally, it provides a high flow resistance at elevated temperatures, ensuring optimal performance under extreme heat conditions.

Torch-free installation

The Endura warm roof build-up features a self-adhesive air and vapour control layer (AVCL), which can be securely bonded to any roof deck without the use of a torch, eliminating hot works risks on site. This makes it a safe, efficient solution for both new-build and refurbishment projects.

Endura and the single layer Airadhesive can also be both part of a full insulated roof system or as part of a waterproof overlay where building requirements allow.

In addition, for suitable non-combustible substrates, Proteus Pro-Felt® Endura AVCL Sanded provides an alternative option, ensuring full compliance with stringent building requirements.

Thermal and waterproofing protection

The system is built up with Proteus Pro-Therm Insulation bonded directly to the AVCL, supported by a polymer-modified, self-adhesive underlay and a choice of capsheets. This multi-layered approach delivers outstanding thermal efficiency, robust waterproofing and long-term resilience, even under challenging site conditions.

As a direct waterproofing overlay or as part of a full Proteus Waterproofing built-up roof system, Proteus Pro-Felt® Endura membranes also provides elastomeric flexibility, high tensile strength and proven performance in demanding environments.

Bespoke system components

The Endura range also includes:

- Endura AVCL – A premium torch-applied vapour barrier for non-combustible substrates.

- Endura SA AVCL – A cold-applied, self-adhesive vapour control membrane with quartz sand surface for secure insulation bonding.

- Endura SA Underlay – An SBS modified self-adhesive underlay for cold-applied systems.

- Endura AIRdhesive – A fleece-backed, single-layer SBS modified membrane designed for superior adhesion and ease of application.

- Endura SA Capsheet – Cold-applied, self-adhesive capsheet with slate mineral finish for durable waterproof protection.

- Endura Mineral Anthracite – A torch-applied cap sheet with enhanced fire performance through graphite additive technology.

Why Choose Proteus Pro-Felt® Endura?

- Tested to Broof(t4) Fire Performance

- Certified for 35 years

- Under normal service conditions, the system will provide a durable waterproofing covering with a service life at least 35 years.

- 30-year Proteus Waterproofing® guarantee

- All products are certified to ISO 900, 14001 and 45001 accreditations

Proteus Pro-Cold® is suitable for new builds and refurbishments and can be used of a range of substrates. It cures to provide a seamless waterproofing protection, making it suitable for use in all climates.

Drip Edge Trim: A Right-angled trim to fulfil a smart finish of the edge of the roof.

Termination Bar: A neat and efficient means of terminating roofing and waterproofing membranes at wall abutments, they require no chases to be cut for installation. Usually used for a Built Up Felt Roof system.

Trims: This high quality, durable roof edge trim is manufactured from glass fibre reinforced polyester. These trims will create a neat, unobtrusive and durable finish for the edge of any flat roof.

F profile: Used for a Built Up Felt Roof System.

A Profile: Used for Mastic Asphalt and a Built-Up Roof System

Ideal for refurbishment projects, Pro-Cryl® can be applied directly to damp substrates and rusted metal. With no primer or additional solar reflection treatment required, Pro-Cryl® offers a fast and efficient cold-application that delivers long term performance, water tightness and protection against UV degradation.

With a rapid installation, Deckmaster offers cost and convenience benefits for both refurbishment and new build projects.

All Deckmaster waterproofing comes with a non-slip surface including a compatible line marking and signage system all of which ensure optimum practicality for all projects. Environmentally friendly with solvent-free, recycled components, Deckmaster can help to meet sustainability targets.

Cold Melt® DPM Primer is a liquid applied, damp proof membrane that can be applied to wet or damp concrete and polymer screeds after three days. This encapsulation of a damp/wet concrete deck will improve the quality and strength of the concrete.

Tapered Roof Design: Proteus Waterproofing can design tapered roof designs starting from the outset of the project.

Part B Fire Roof Design:

Low Threshold Terrace & Balcony Design:

Thermal Calculation & Condensation Risk:

When specifying or installing a Pro-Living® roof using Proteus’ unique Cold Melt® membrane, you are combining environment friendly materials such as recycled rubber crumb and organically grown products.

Choosing a Pro-Living® green or bio-diverse system from Proteus can provide ecological benefits and more; energy efficiency is enhanced too. Studies show a building’s internal air temperature remains more constant; hotter in winter and cooler in summer meaning air conditioning and heating systems are relied upon less.

Pro-Living® can help you to create a rooftop garden or communal space, a pleasant environment in which to spend time. Terraces can offer additional living space when created using a Proteus paving system. Walkways can meander through bio-diversity

Ideal for both refurbishments and new builds, Pro-BW® Plus is suitable for a variety of external applications. As it is a cold applied installation, the system meets health and safety criteria by minimising risk to both operatives and members of the public. Pro-BW® Plus reduces installation time from days to hours, is made in the UK and is BBA Certified.

In the dynamic field of construction, where effective moisture management is essential, the Proteus Hot Melt® system from Proteus Waterproofing Limited delivers a monolithic waterproofing layer suitable for various roof types. This hot-applied system, certified under British Board of Agrément (BBA) Certificate 22/6186, aligns with UK Building Regulations and provides a bonded membrane for flat roofs, terraces, podiums, and more. Architects, contractors, and property owners can rely on its documented performance for projects requiring consistent waterproofing.

This article examines the system's documented attributes and advantages, outlines general installation procedures, and discusses its compatibility with inverted roofs, blue roofs through the Attenu8® system, and green roofs via the Pro-Living® range. Based on technical specifications and guidelines, it highlights how Proteus Hot Melt® contributes to functional roofing designs.

Attributes and Advantages of Proteus Hot Melt®

The Proteus Hot Melt® system consists of a hot-melt compound, polyester reinforcement mesh, and a mineral-surfaced capsheet, forming a continuous membrane assessed for performance in demanding conditions.

Assessed Performance Characteristics

• Weathertightness: The system prevents moisture ingress into the building, as evaluated in the BBA Certificate, making it applicable for inverted flat roofs (including zero falls), terraces, podiums, balconies, blue roofs, green roofs, and roof gardens.

• Fire Performance: In specified protected configurations, the system achieves classifications that allow unrestricted use under Building Regulations, such as Requirement B4(2) in England and Wales, and Standard 2.8 in Scotland. Restrictions apply to balconies, and project-specific classifications should be confirmed.

• Wind Uplift Resistance: The system's bond withstands wind loads, with performance tied to the roofing specification's upper layers, as per BBA assessments.

• Mechanical Resistance: It accommodates limited foot traffic during installation and maintenance, as well as minor structural movements, without damage.

• Root Resistance: Combined with Proteus Hot Melt Anti-Root Plain Capsheet, it resists root penetration, supporting green roof applications.

• Service Life: When protected (e.g., by insulation or ballast), the system maintains waterproofing for the roof's expected lifespan, based on BBA evaluations.

Practical Considerations

• Application Range: Compatible with substrates like concrete and various finishes, allowing use across multiple project elements.

• Monolithic Structure: The application method minimizes potential weak points from seams, as detailed in installation guides.

• Installation Efficiency: The pour-and-roll technique supports coverage with controlled material use.

Selecting Proteus Hot Melt® allows integration with roofing designs that meet documented standards.

General Installation Procedures for Proteus Hot Melt®

Preparation and Safety Measures

• Health and Safety: Perform risk assessments and equip with PPE, such as heat-resistant gloves and eye protection. Adhere to Safety Datasheets and CLP Regulations for handling, with precautions against fire risks.

• Storage and Handling: Keep components dry at 5–25°C for up to 12 months. Handle 25kg blocks manually and shield from weather on-site.

• Tools and Equipment: Use boilers (heating to 180–200°C), rollers, and safety items like harnesses. Clean with solvent wipes after use.

• Substrate Readiness: Inspect and repair (e.g., remove concrete laitance), clean via sweeping or vacuuming, and dry fully. Conduct adhesion tests on each area.

• Priming: Apply DPM Primer at 0.2–0.3 l/m² with rollers or brushes, drying in 1–2 hours.

Installation Steps

1. Compound Heating and Application: Maintain boiler temperatures at 190°C target. Apply at 1.5–2 kg/m² via pour-and-roll for uniform distribution. Seal incomplete sections daily.

2. Reinforcement Mesh (Proteus Hot Melt® Force): Position polyester mesh, securing as needed, and embed in compound.

3. Capsheet Placement: Prepare rolls, pour compound, and roll for adhesion with 100mm side laps and 150mm end laps. Proceed from low to high points on flat areas.

4. Detail Work: Reinforce upstands, outlets, penetrations, joints, and edges with extra layers for seals.

5. Adaptations: For zero-fall roofs, incorporate drainage per design standards. Inverted setups place insulation over the membrane.

Quality Assurance and Upkeep

• Verification: Include site inspections, integrity tests (e.g., flooding), and daily reviews with records.

• Maintenance: Check twice yearly for blockages or wear, clearing drains and addressing issues with matching materials.

• Guarantees: Available post-installation by certified contractors, covering system performance.

These procedures, supported by Proteus training, align with standards for consistent outcomes.

Compatibility with Inverted Roofs

Inverted roofs position insulation above the waterproofing, and Proteus Hot Melt® supports this by providing a protected membrane that reduces exposure to temperature fluctuations and UV.

• Advantages: Minimizes thermal bridging and aids energy performance, with options for ballast or paving.

• Installation Notes: Apply directly to the deck, then add insulation and filters. Suitable for zero-fall layouts with appropriate drainage.

Integration with Blue Roofs: The Attenu8® System

Proteus Hot Melt® works with the Attenu8® blue roof for stormwater management, using modular cells to store and release water at rates as low as 0.07 l/s via flow restrictors.

• Functionality: The membrane serves as the base, with Attenu8® forming a void above and a secondary layer for added security. Overflows manage high volumes per BS EN 12056-3:2000.

• Advantages: Reduces runoff peaks, supports planning compliance (e.g., London Plan), and avoids flotation in inverted designs, enabling sloped roof adaptations.

• Flood Management Alignment: Detains rainfall to lessen flood risks, fitting Property Flood Resilience principles for new and existing structures.

• Installation: Build on the Hot Melt® layer, secure components with tapes, and top with finishes like paving or green roof.

Compatibility with Green Roofs: The Pro-Living® Range

Proteus Hot Melt® also pairs with Pro-Living® for vegetated roofs, incorporating sedum, wildflower, or diverse plant layers.

• Suitability: Use the Anti-Root Capsheet to prevent root ingress, maintaining membrane integrity under vegetation.

• Advantages: Contributes to drainage systems, moderates urban temperatures, and supports plant growth per BS 8217.

• Installation: Layer over the membrane with root barriers, then add substrates and plants. Inspect annually for drainage and debris.

• Applications: Effective for roof gardens handling soil loads.

Training, Assistance, and Assurances

Proteus provides site-based training on substrate assessment, application, and detailing, issuing 24-month certification cards (renewable). This supports compliant installations qualifying for guarantees.

In conclusion, Proteus Hot Melt® forms a verified base for roofing systems, compatible with inverted, blue (Attenu8®), and green (Pro-Living®) configurations. For specifications or inquiries, reach Proteus Waterproofing at enquiries@proteuswaterproofing.co.uk . Choose documented solutions for lasting roof performance.

Key Highlights

- Versatile Applications: Suitable for inverted roofs, podium decks, green roofs, balconies, terraces, and blue roofs as part of the Attenu8® water attenuation system

- Overlay Compatibility: Can be applied over existing single-ply, felt or asphalt surfaces in inverted roofs after removing finishes and insulation, allowing reinstatement of finishes on completion.

- Accelerated Installation: Features Cold Melt® DPM Primer, enabling application on substrates with up to 98% RH after just 3 days of concrete curing (subject to adhesion testing)

- Performance Benefits: Remains flexible without becoming brittle over time; no odour during application due to 100% solids content; tested to BS EN 1504-2 for protective coating

What makes Attenu8® different?

At the heart of the Attenu8® system lies the ACO Technologies patented drainage and overflow layer that separates water attenuation from the underlying roof drainage. This unique structure allows the drainage system to be independently engineered in line with BS EN12056:3 2000, unlike many competitor systems that obscure or override essential hydraulic principles.

This matters. Precise compliance with BS EN12056:3 enables engineers to accurately calculate flow rates under worst-case rainfall events, protecting clients from design errors, contractual disputes and regulatory non-compliance.

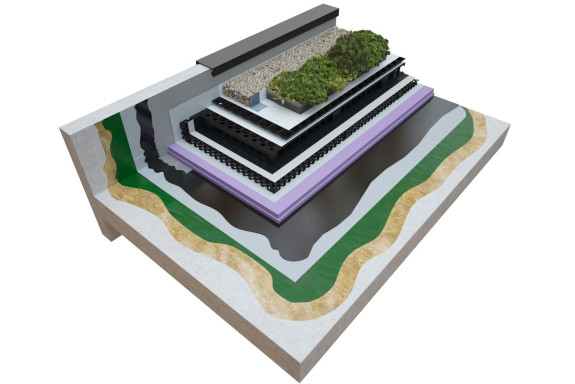

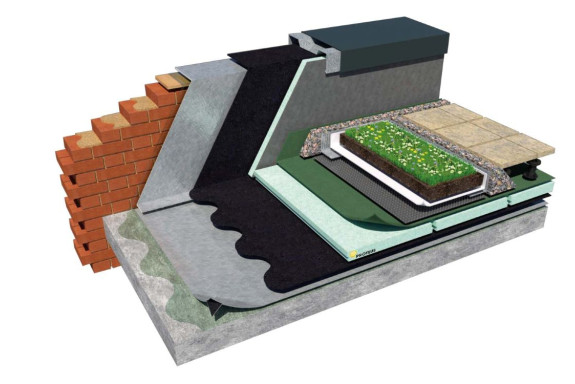

Cold Melt Blue Roof Build Up

Cold Melt Blue Roof Build Up

Technical advantages at a glance

- Fully compliant with BS EN12056:3 and BS6229:2018.

- Eliminates negative thermal performance in inverted roof designs.

- Reduces required inverted insulation thickness, saving build height and cost.

- Mitigates flotation risk without extra ballast, supporting lighter structural designs.

- Compatible with substrates laid to falls (meeting NHBC and LABC preferences).

- Ideal for new builds and refurbishments on existing falls-based structures.

- Provides secondary waterproofing membrane for high-risk buildings.

- Integrated overflow mechanism to meet 100-year rainfall events.

- Full support for green roofs and bio-solar integration.

- Re-usable, in line with circular economy principles in the London Plan.

- Effective silt and debris management.

- Easy to inspect and maintain in accordance with GRO and CIRIA C817.

- Contributes to BREEAM when used with rainwater harvesting.

- Reduces or eliminates need for below-ground attenuation tanks

Optimised for performance and circularity

The Attenu8® system is not just designed for compliance - it’s built for resilience. Its hybrid approach ensures thermal and hydraulic calculations are aligned, allowing for reduced design depths without compromising performance. It is also ideally suited to circular building practices, offering:

- Reduced drain-down times that match hydraulic calculations.

- All-year-round installation capability.

- Full reusability and compatibility with circular building goals.

- BBA certified to last for the life of the building, once covered, on which it is installed.

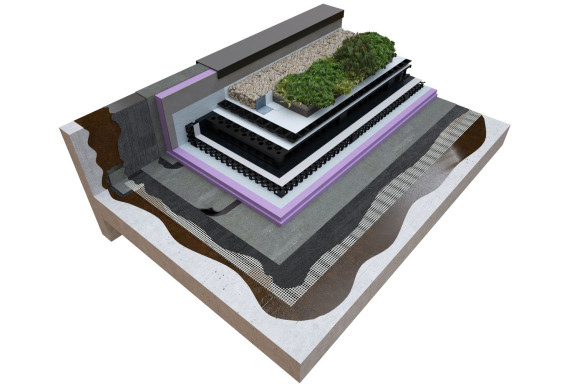

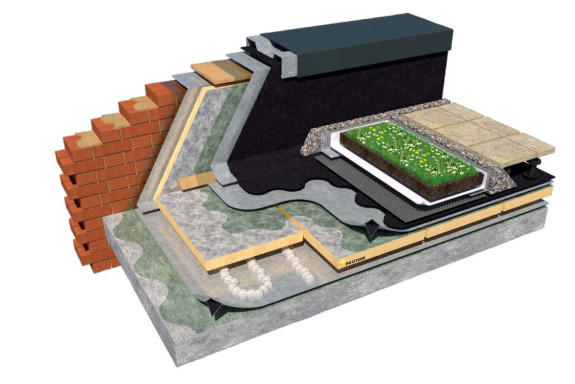

Hot Melt Blue Roof Build Up

Hot Melt Blue Roof Build Up

The total integrated specification

The Attenu8® solution is more than just a blue roof - it's a fully integrated system covering:

- Waterproofing

- Thermal insulation

- Water attenuation

- Drainage

- Green or solar roof compatibility

- Compliance with planning, SuDS, and fire regulations

This joined-up approach reduces design risk, ensures consistent performance and removes the duplication and rework that often results from multi-supplier installations. By choosing Attenu8®, architects and specifiers gain certainty in performance and delivery, reducing pressure on the design team and supporting a "right first time" approach.

Guaranteed peace of mind

All Attenu8® systems are:

- Installed only by approved Proteus contractors.

- Covered by a single, insurance-backed warranty.

- Backed by the combined expertise of Proteus Waterproofing and ACO Technologies

- Supported by full technical documentation and installation guidance.

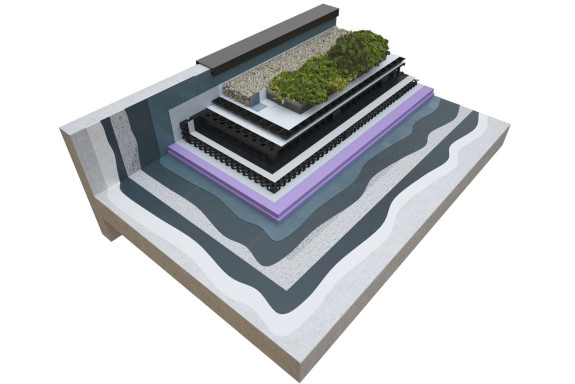

Pro BW Roof Build Up

Pro BW Roof Build Up

Applications across all sectors

Attenu8® is ideal for a wide range of different application including:

- Commercial buildings

- Residential and mixed-use schemes

- Data centres and critical infrastructure

- Education facilities

- Healthcare environments

- Ministry of Defence and government buildings

- Retrofit projects requiring SuDS compliance

Also include refurbishment properties with existing roofs with falls

Wherever water needs to be controlled, Attenu8® delivers precision, reliability, and compliance.

Start Your Project with Confidence

Whether you are in the early planning stages or developing detailed specifications, our team is here to help. We work with architects, specifiers and contractors to simplify the process - from technical advice and system design through to installation and post-completion support. To discuss your project or request a technical consultation, contact our expert team or download our Attenu8® specification guide.

Product Overview

Building on its role as a seamless, cold-applied waterproofing solution, Cold Melt® integrates sustainable materials like recycled rubber crumb and castor oil for enhanced environmental credentials. This fully bonded system cures to form a monolithic membrane that's ideal for complex projects, with no fire risk during installation.

Core Components

- Cold Melt®: Applied via trowel or squeegee it offers elastomeric flexibility to accommodate movement without cracking

- Pro-Carrier SA: Allows instillation over a wide range of substrates including timber decks. Provides extra tensile strength to the system and crack capability.

- Pro-Primer SA: Self-adhesive primer for Pro-Carrier SA.

- DPM Primer: Speeds up workflows on damp / wet concrete substrates, (green concrete), allowing overlay once primer is cured, often just 3 days post-pour.

- Cold Melt® UV Top: Protects exposed Cold Melt® sections with pigmented protection, resisting UV degradation for long-term aesthetics in colours like Mid Grey, red blue, safety yellow.

Key Applications

From refurbishing failed single-ply, felt or asphalt layers in existing inverted setups (by stripping back finishes, and overlaying) to new builds, Cold Melt® excels in high-moisture environments. It's a core element of our Attenu8 system for stormwater management, seamlessly incorporating blue roof attenuation where needed.

Product Overview

Product Overview

Key Benefits and USPs

Cold Melt® stands out in roof waterproofing by combining sustainability, efficiency, and performance. Here's why it's a preferred choice for contractors and specifiers:

- Sustainable Composition: Blends recycled rubber crumb with castor oil and other components for reduced environmental impact, supporting green building practices without compromising durability

- Safe: Cold Application avoids risk of fire associated with hot-applied systems, ideal for occupied buildings

- Flexible and Long-Lasting: Elastomeric properties ensure it accommodates substrate movement and remains pliable over time, as validated by BBA testing for protected roof applications.

- Refurbishment Efficiency: Easily overlays existing single-ply, felt or asphalt membranes in inverted roofs—simply remove and reinstate finishes for minimal disruption and cost savings

- Project Acceleration: The DPM Primer enables application on high-moisture substrates (up to 98% RH per BS 8203) after just 3 days of concrete curing, slashing traditional wait times

- Integrated Sustainability: Forms a key part of the Attenu8 system for effective stormwater management, adaptable for blue roof attenuation to enhance urban resilience.

- Maintenance Simplicity: Designed for longevity with straightforward upkeep. Recommended bi-annual debris clearance and inspections of the finished roof surface finishes as detailed in our Roof Maintenance Guide, help maintain performance.

Applications and Uses

Cold Melt offers versatile waterproofing for a range of protected roof and podium configurations, delivering reliable performance in both new builds and refurbishments. It's particularly effective in scenarios requiring minimal disruption and compatibility with existing structures.

Primary Applications

- Inverted Roofs and Podium Decks: Provides a seamless barrier in buried or protected setups, with insulation above the membrane for thermal efficiency

- Green Roofs and Roof Gardens: Supports vegetation layers, enhancing biodiversity while ensuring waterproof integrity—regular vegetation control per our Maintenance Guide is advised

- Balconies and Terraces: Ideal for pedestrian-access areas once covered / protected

- Blue Roofs as Part of Attenu8 System: Integrates with water attenuation designs for stormwater management; can include or exclude blue roof elements. Recommended Blue Roof drainage inspection chambers inspected monthly for optimal function

- Refurbishment Over Existing Surfaces: Overlays single-ply, felt or asphalt membranes in inverted roofs—remove finishes and insulation, apply Cold Melt®, then reinstate layers for cost-effective upgrades

Compatible with substrates such as concrete, timber, metal, and asphalt, ensuring broad project suitability.

Designed Components

Cold Melt® incorporates elements that enhance installation efficiency and long-term performance, setting it apart in liquid waterproofing solutions. These components ensure seamless integration in demanding environments, from high-moisture substrates to UV-exposed areas.

Standout Features

- DPM Primer: This two-component primer can be laid as a Barrier Primer against residual moisture in newly laid concrete / screed substrates, (green concrete), allowing application at up to 98% RH (BS 8203). It cuts overlay of a newly poured concrete deck/screed to as little as 3 days post-pour, enabling faster project progression without compromising bond strength

- UV Top: A pigmented polyurethane sealer for exposed membrane sections on upstans, offering UV stability and colour options. Applied at 0.75 kg/m², tested to BS EN 1504-2 for durable protection

- Attenu8 Integration: As a core of our water attenuation system, Cold Melt® supports blue roof designs for stormwater control

These innovations streamline workflows while prioritising sustainability and safety

Technical Specifications

Cold Melt® delivers reliable performance across key metrics, backed by rigorous testing. Below is a summary of essential data for planning and installation—always refer to full datasheets for site-specific details.

Coverage and Application Rates

Component | Coverage Rate | Coats | Substrates |

|---|---|---|---|

Pro-Prime® SA | 0.2 L/m² | 1 | All prepared surfaces |

Pro-Carrier SA | 1m2 1m2 | 1 | All primed substrates |

Cold Melt® (Horizontal) | 2.5 kg/m² | 1 | Concrete, timber, metal, asphalt |

Cold Melt® (Vertical) | 1.25 kg/m² | 2 | As above |

Cold Melt® UV Top | 0.75 kg/m² | 1 | Exposed membrane areas |

Drying and Curing Times (at 20°C)

Component | Touch Dry | Foot Traffic Ready | Fully Cured |

|---|---|---|---|

Pro-Prime® SA | 30-60 minutes | - | Dry to touch |

Pro-Carrier SA | 0 | Immediately | - |

Cold Melt® | 6-36 hours | 8 | Once cured |

Cold Melt® UV Top | - | 24 hours | Once Cured |

Times vary with temperature, thickness, and porosity—protect from moisture during curing to avoid issues.

Packaging and Colours

Available in pre-proportioned units for accurate mixing.

UV Top offers colours including Black, Dark Grey, Mid Grey, Green, Light Blue, Red, Safety Yellow, and more.

Performance Standards

- Tested to BS EN 1504-2 as a protective waterproof coating

- Accommodates up to 98% RH substrates (BS 8203) with DPM Primer

For maintenance, our Proteus Maintenance Guide recommends bi-annual checks for inverted systems

Inverted Green Roof Detail

Inverted Green Roof Detail

Certifications and Compliance

Cold Melt® meets stringent industry standards for performance and safety in protected roof waterproofing, ensuring reliable results when specified, installed, and maintained correctly. Our commitment to clear, accurate information aligns with CCPI guidelines, avoiding unsubstantiated claims while providing verifiable data.

Key Certifications

- BBA Agrément Certificate 23/6654: Validates Cold Melt® for use as a protected waterproofing layer in inverted roofs, flat roofs, podium decks, balconies, warm roofs, blue roofs, green roofs and roof gardens, including zero fall roofs, confirming durability under normal service conditions in protected applications

- BS EN 1504-2 Compliance: Tested as a protective waterproof coating, with UV Top offering UV stability for exposed areas

- BS 8203 and BS 6229 Alignment: Supports high-moisture substrates (up to 98% RH) and minimum falls of 1:80 for effective drainage

To maintain compliance and guarantee validity, follow our Proteus Maintenance Guide.

Warm Green Roof Detail

Warm Green Roof Detail

Installation and Best Practices

Cold Melt® is designed for straightforward, safe application by trained professionals, minimising downtime and risks. Follow these guidelines for optimal results in protected roof systems—always consult full datasheets and conduct adhesion tests where required.

Preparation Steps

- Substrate Readiness: Ensure surfaces are sound, clean, dry, and free from defects, oil, dust, or corrosion (per BS 8203). Repair cracks >0.5mm and achieve minimum 1:80 fall for drainage (BS 6229). Tested for zero fall for installation of Blue Roofs.

- Concrete/screeds Prime wet/damp: Use DPM Primer to accommodate up to 98% RH in substrates prior to Cold Melt® overlay. Applied by roller/brush

- Priming: All surfaces, apply Pro-Prime® SA by roller/brush

- Pro-Carrier SA: To all primed surfaces install Pro-Carrier SA

Application Process

COLD MELT®:

- Mixing: Stir resin, add hardener, and mix at 300-400 rpm for 2 minutes, avoid part-mixing

- Membrane Application: Spread Cold Melt® using trowel or squeegee (2.5 kg/m² horizontal, 1.25 kg/m² vertical in two coats). Lightly roll surface with ribbed roller to eliminate roller marks and allow 6-36 hours curing dependant on air /substrate temperature

- Exposed detail Areas: Top with a coat of UV Top at 0.75 kg/m² via brush/roller for UV protection

- Details: Use pitch pockets for complex areas

- Testing on Completions and Prior to covering : perform wet electronic leak tests on buried systems prior to being covered

Best Practices for Longevity

Adhere to our Proteus Maintenance Guide: Post-installation, schedule bi-annual inspections for debris, vegetation, and structural integrity in inverted or green setups to preserve performance.

Case Studies and Resources

Explore real-world applications of Cold Melt® through our case studies, showcasing its performance in diverse projects. These case studies provide practical insights into seamless waterproofing for protected roofs, helping you visualise outcomes for your own specifications.

FAQs

Find quick answers to common questions about Cold Melt® below. For more details, explore our resources or reach out directly.

What makes Cold Melt® a suitable alternative to traditional mastic asphalt or hot melt systems?

Cold Melt® is a cold-applied polyurethane membrane that eliminates fire risks and odours during installation, incorporating recycled materials for sustainability. It's BBA-certified for protected roofs and remains elastomeric over time, avoiding brittleness.

Can Cold Melt® be applied over existing roof surfaces?

Yes, it's compatible for overlaying single-ply, timber, felt or asphalt membranes in inverted roofs. Remove finishes and insulation, prepare the substrate, apply the system, and reinstate layers for efficient refurbishments.

How does the DPM Primer accelerate roof projects?

This primer allows installation on substrates with up to 98% relative humidity (per BS 8203), reducing concrete overlay times to a minimum of 3 days after pouring, subject to adhesion testing—speeding up timelines significantly.

What maintenance is required for Cold Melt® systems?

Follow our Proteus Maintenance Guide: Conduct bi-annual visual inspections, clear debris, and monitor for issues like vegetation in green roofs or outlet function in blue roof setups within the Attenu8 system.

Is Cold Melt® suitable for zero-fall roofs?

Absolutely—it's certified for zero-fall designs in protected configurations.

How does Cold Melt® integrate with blue roofs?

As part of the Attenu8 system, it supports water attenuation for stormwater management. Maintenance includes monthly drainage outlet checks to ensure reliable operation of the Blue Roof.

What are the environmental benefits of using Cold Melt®?

Cold Melt® as stated by the BBA once covered may last the life of the structure it is laid on. This therefore minimises land fill as the roof system does not require re=placing through the life of the building.

Cold Melt® incorporates recycled rubber crumb and castor oil, reducing environmental impact while providing a seamless, durable membrane. Its cold application removes the risk of fire. It also supports sustainable building practices in green and blue roof designs. When fully protected and under normal service conditions, the system will have a service life equivalent to the structure in which it is incorporated.

When should the UV Top coat be used, and what colours are available?

UV Top is applied to exposed upstand areas of the Cold Melt® membrane for UV stability and aesthetics, tested to BS EN 1504-2. It comes in a range of colours including Mid Grey, Dark Grey, Black, Green, Red, and Safety Yellow, with pre-proportioned units for easy mixing.

How long does installation typically take for a Cold Melt® system?

Installation is efficient, with priming taking 30-60 minutes to dry, membrane curing in 6-36 hours, and full system readiness for foot traffic in 24 hours at 20°C. The DPM Primer can further accelerate projects on damp/wet concrete substrates times vary by site conditions.

Is Cold Melt® compatible with different types of insulation?

Yes, it's suitable for use with various insulation materials in inverted or protected warm roof setups. Contact our team for guidance on integration to ensure thermal performance and avoid settlement issues, as per our Proteus Maintenance Guide.

What warranty options are available for Cold Melt® installations?

When installed by approved contractors and maintained according to our guidelines, Cold Melt® systems are backed by comprehensive guarantees tailored to the project. The BBA certification confirms durability for the design life of the roof in protected applications.

FAQs

-

What makes Attenu8® different from other blue roof systems?

Attenu8® features patented ACO Technologies drainage that separates water attenuation from roof drainage, allowing precise BS EN12056:3 compliant calculations under worst-case rainfall events. You also benefit from single-point design responsibility with one insurance-backed warranty covering all system components.

-

What’s included in the Attenu8® system?

Attenu8® provides a complete integrated solution including waterproofing membrane (Cold Melt®, Hot Melt®, or Pro-BW® Plus), thermal insulation, water attenuation, drainage, and compatibility with green roofs or solar panels. The package includes full technical design, approved contractor installation, and comprehensive insurance-backed guarantees.

-

Who can install an Attenu8® system?

Attenu8® is installed exclusively by Proteus-approved contractors who have undergone specialist training. This ensures consistent quality, proper installation, and full warranty compliance backed by our insurance guarantee.

-

Does Attenu8® comply with UK building regulations and SuDS requirements?

Yes, Attenu8® is fully compliant with BS EN12056:3 and BS6229:2018, and is BBA certified to last for the building's lifetime. It meets SuDS requirements for stormwater management and can contribute to BREEAM certification when used with rainwater harvesting.

-

Can Attenu8® reduce my building costs and construction programme?

Yes, Attenu8® reduces required insulation thickness and eliminates the need for excessive ballast, saving both build height and material costs. Single-point specification eliminates coordination issues between multiple suppliers, reducing design time and accelerating construction.