Call us on

+44 (0)1268 777871Cold Melt®

Cold Melt® is a two-part elastomeric polyurethane membrane that delivers seamless leak protection for protected roofs, including zero fall designs. Incorporating recycled rubber crumb and castor oil, this BBA-certified system (Certificate 23/6654) provides durable waterproofing when installed and maintained as specified.

Key Highlights

- Versatile Applications: Suitable for inverted roofs, podium decks, green roofs, balconies, terraces, and blue roofs as part of the Attenu8® water attenuation system

- Overlay Compatibility: Can be applied over existing single-ply, felt or asphalt surfaces in inverted roofs after removing finishes and insulation, allowing reinstatement of finishes on completion.

- Accelerated Installation: Features Cold Melt® DPM Primer, enabling application on substrates with up to 98% RH after just 3 days of concrete curing (subject to adhesion testing)

- Performance Benefits: Remains flexible without becoming brittle over time; no odour during application due to 100% solids content; tested to BS EN 1504-2 for protective coating

Product Overview

Building on its role as a seamless, cold-applied waterproofing solution, Cold Melt® integrates sustainable materials like recycled rubber crumb and castor oil for enhanced environmental credentials. This fully bonded system cures to form a monolithic membrane that's ideal for complex projects, with no fire risk during installation.

Core Components

- Cold Melt®: Applied via trowel or squeegee it offers elastomeric flexibility to accommodate movement without cracking

- Pro-Carrier SA: Allows instillation over a wide range of substrates including timber decks. Provides extra tensile strength to the system and crack capability.

- Pro-Primer SA: Self-adhesive primer for Pro-Carrier SA.

- DPM Primer: Speeds up workflows on damp / wet concrete substrates, (green concrete), allowing overlay once primer is cured, often just 3 days post-pour.

- Cold Melt® UV Top: Protects exposed Cold Melt® sections with pigmented protection, resisting UV degradation for long-term aesthetics in colours like Mid Grey, red blue, safety yellow.

Key Applications

From refurbishing failed single-ply, felt or asphalt layers in existing inverted setups (by stripping back finishes, and overlaying) to new builds, Cold Melt® excels in high-moisture environments. It's a core element of our Attenu8 system for stormwater management, seamlessly incorporating blue roof attenuation where needed.

Product Overview

Product Overview

Key Benefits and USPs

Cold Melt® stands out in roof waterproofing by combining sustainability, efficiency, and performance. Here's why it's a preferred choice for contractors and specifiers:

- Sustainable Composition: Blends recycled rubber crumb with castor oil and other components for reduced environmental impact, supporting green building practices without compromising durability

- Safe: Cold Application avoids risk of fire associated with hot-applied systems, ideal for occupied buildings

- Flexible and Long-Lasting: Elastomeric properties ensure it accommodates substrate movement and remains pliable over time, as validated by BBA testing for protected roof applications.

- Refurbishment Efficiency: Easily overlays existing single-ply, felt or asphalt membranes in inverted roofs—simply remove and reinstate finishes for minimal disruption and cost savings

- Project Acceleration: The DPM Primer enables application on high-moisture substrates (up to 98% RH per BS 8203) after just 3 days of concrete curing, slashing traditional wait times

- Integrated Sustainability: Forms a key part of the Attenu8 system for effective stormwater management, adaptable for blue roof attenuation to enhance urban resilience.

- Maintenance Simplicity: Designed for longevity with straightforward upkeep. Recommended bi-annual debris clearance and inspections of the finished roof surface finishes as detailed in our Roof Maintenance Guide, help maintain performance.

Applications and Uses

Cold Melt offers versatile waterproofing for a range of protected roof and podium configurations, delivering reliable performance in both new builds and refurbishments. It's particularly effective in scenarios requiring minimal disruption and compatibility with existing structures.

Primary Applications

- Inverted Roofs and Podium Decks: Provides a seamless barrier in buried or protected setups, with insulation above the membrane for thermal efficiency

- Green Roofs and Roof Gardens: Supports vegetation layers, enhancing biodiversity while ensuring waterproof integrity—regular vegetation control per our Maintenance Guide is advised

- Balconies and Terraces: Ideal for pedestrian-access areas once covered / protected

- Blue Roofs as Part of Attenu8 System: Integrates with water attenuation designs for stormwater management; can include or exclude blue roof elements. Recommended Blue Roof drainage inspection chambers inspected monthly for optimal function

- Refurbishment Over Existing Surfaces: Overlays single-ply, felt or asphalt membranes in inverted roofs—remove finishes and insulation, apply Cold Melt®, then reinstate layers for cost-effective upgrades

Compatible with substrates such as concrete, timber, metal, and asphalt, ensuring broad project suitability.

Designed Components

Cold Melt® incorporates elements that enhance installation efficiency and long-term performance, setting it apart in liquid waterproofing solutions. These components ensure seamless integration in demanding environments, from high-moisture substrates to UV-exposed areas.

Standout Features

- DPM Primer: This two-component primer can be laid as a Barrier Primer against residual moisture in newly laid concrete / screed substrates, (green concrete), allowing application at up to 98% RH (BS 8203). It cuts overlay of a newly poured concrete deck/screed to as little as 3 days post-pour, enabling faster project progression without compromising bond strength

- UV Top: A pigmented polyurethane sealer for exposed membrane sections on upstans, offering UV stability and colour options. Applied at 0.75 kg/m², tested to BS EN 1504-2 for durable protection

- Attenu8 Integration: As a core of our water attenuation system, Cold Melt® supports blue roof designs for stormwater control

These innovations streamline workflows while prioritising sustainability and safety

Technical Specifications

Cold Melt® delivers reliable performance across key metrics, backed by rigorous testing. Below is a summary of essential data for planning and installation—always refer to full datasheets for site-specific details.

Coverage and Application Rates

Component | Coverage Rate | Coats | Substrates |

|---|---|---|---|

Pro-Prime® SA | 0.2 L/m² | 1 | All prepared surfaces |

Pro-Carrier SA | 1m2 1m2 | 1 | All primed substrates |

Cold Melt® (Horizontal) | 2.5 kg/m² | 1 | Concrete, timber, metal, asphalt |

Cold Melt® (Vertical) | 1.25 kg/m² | 2 | As above |

Cold Melt® UV Top | 0.75 kg/m² | 1 | Exposed membrane areas |

Drying and Curing Times (at 20°C)

Component | Touch Dry | Foot Traffic Ready | Fully Cured |

|---|---|---|---|

Pro-Prime® SA | 30-60 minutes | - | Dry to touch |

Pro-Carrier SA | 0 | Immediately | - |

Cold Melt® | 6-36 hours | 8 | Once cured |

Cold Melt® UV Top | - | 24 hours | Once Cured |

Times vary with temperature, thickness, and porosity—protect from moisture during curing to avoid issues.

Packaging and Colours

Available in pre-proportioned units for accurate mixing.

UV Top offers colours including Black, Dark Grey, Mid Grey, Green, Light Blue, Red, Safety Yellow, and more.

Performance Standards

- Tested to BS EN 1504-2 as a protective waterproof coating

- Accommodates up to 98% RH substrates (BS 8203) with DPM Primer

For maintenance, our Proteus Maintenance Guide recommends bi-annual checks for inverted systems

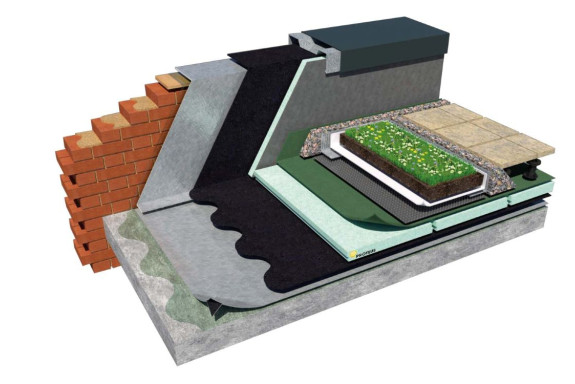

Inverted Green Roof Detail

Inverted Green Roof Detail

Certifications and Compliance

Cold Melt® meets stringent industry standards for performance and safety in protected roof waterproofing, ensuring reliable results when specified, installed, and maintained correctly. Our commitment to clear, accurate information aligns with CCPI guidelines, avoiding unsubstantiated claims while providing verifiable data.

Key Certifications

- BBA Agrément Certificate 23/6654: Validates Cold Melt® for use as a protected waterproofing layer in inverted roofs, flat roofs, podium decks, balconies, warm roofs, blue roofs, green roofs and roof gardens, including zero fall roofs, confirming durability under normal service conditions in protected applications

- BS EN 1504-2 Compliance: Tested as a protective waterproof coating, with UV Top offering UV stability for exposed areas

- BS 8203 and BS 6229 Alignment: Supports high-moisture substrates (up to 98% RH) and minimum falls of 1:80 for effective drainage

To maintain compliance and guarantee validity, follow our Proteus Maintenance Guide.

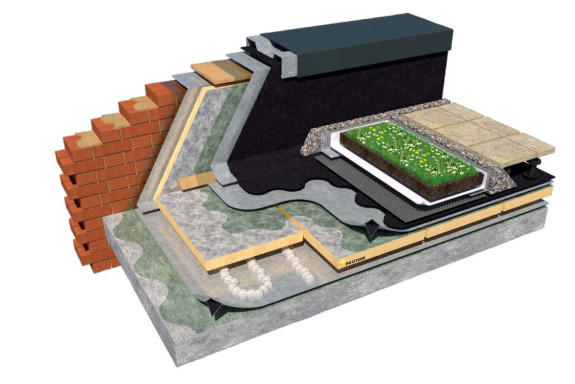

Warm Green Roof Detail

Warm Green Roof Detail

Installation and Best Practices

Cold Melt® is designed for straightforward, safe application by trained professionals, minimising downtime and risks. Follow these guidelines for optimal results in protected roof systems—always consult full datasheets and conduct adhesion tests where required.

Preparation Steps

- Substrate Readiness: Ensure surfaces are sound, clean, dry, and free from defects, oil, dust, or corrosion (per BS 8203). Repair cracks >0.5mm and achieve minimum 1:80 fall for drainage (BS 6229). Tested for zero fall for installation of Blue Roofs.

- Concrete/screeds Prime wet/damp: Use DPM Primer to accommodate up to 98% RH in substrates prior to Cold Melt® overlay. Applied by roller/brush

- Priming: All surfaces, apply Pro-Prime® SA by roller/brush

- Pro-Carrier SA: To all primed surfaces install Pro-Carrier SA

Application Process

COLD MELT®:

- Mixing: Stir resin, add hardener, and mix at 300-400 rpm for 2 minutes, avoid part-mixing

- Membrane Application: Spread Cold Melt® using trowel or squeegee (2.5 kg/m² horizontal, 1.25 kg/m² vertical in two coats). Lightly roll surface with ribbed roller to eliminate roller marks and allow 6-36 hours curing dependant on air /substrate temperature

- Exposed detail Areas: Top with a coat of UV Top at 0.75 kg/m² via brush/roller for UV protection

- Details: Use pitch pockets for complex areas

- Testing on Completions and Prior to covering : perform wet electronic leak tests on buried systems prior to being covered

Best Practices for Longevity

Adhere to our Proteus Maintenance Guide: Post-installation, schedule bi-annual inspections for debris, vegetation, and structural integrity in inverted or green setups to preserve performance.

Case Studies and Resources

Explore real-world applications of Cold Melt® through our case studies, showcasing its performance in diverse projects. These case studies provide practical insights into seamless waterproofing for protected roofs, helping you visualise outcomes for your own specifications.

FAQs

Find quick answers to common questions about Cold Melt® below. For more details, explore our resources or reach out directly.

What makes Cold Melt® a suitable alternative to traditional mastic asphalt or hot melt systems?

Cold Melt® is a cold-applied polyurethane membrane that eliminates fire risks and odours during installation, incorporating recycled materials for sustainability. It's BBA-certified for protected roofs and remains elastomeric over time, avoiding brittleness.

Can Cold Melt® be applied over existing roof surfaces?

Yes, it's compatible for overlaying single-ply, timber, felt or asphalt membranes in inverted roofs. Remove finishes and insulation, prepare the substrate, apply the system, and reinstate layers for efficient refurbishments.

How does the DPM Primer accelerate roof projects?

This primer allows installation on substrates with up to 98% relative humidity (per BS 8203), reducing concrete overlay times to a minimum of 3 days after pouring, subject to adhesion testing—speeding up timelines significantly.

What maintenance is required for Cold Melt® systems?

Follow our Proteus Maintenance Guide: Conduct bi-annual visual inspections, clear debris, and monitor for issues like vegetation in green roofs or outlet function in blue roof setups within the Attenu8 system.

Is Cold Melt® suitable for zero-fall roofs?

Absolutely—it's certified for zero-fall designs in protected configurations.

How does Cold Melt® integrate with blue roofs?

As part of the Attenu8 system, it supports water attenuation for stormwater management. Maintenance includes monthly drainage outlet checks to ensure reliable operation of the Blue Roof.

What are the environmental benefits of using Cold Melt®?

Cold Melt® as stated by the BBA once covered may last the life of the structure it is laid on. This therefore minimises land fill as the roof system does not require re=placing through the life of the building.

Cold Melt® incorporates recycled rubber crumb and castor oil, reducing environmental impact while providing a seamless, durable membrane. Its cold application removes the risk of fire. It also supports sustainable building practices in green and blue roof designs. When fully protected and under normal service conditions, the system will have a service life equivalent to the structure in which it is incorporated.

When should the UV Top coat be used, and what colours are available?

UV Top is applied to exposed upstand areas of the Cold Melt® membrane for UV stability and aesthetics, tested to BS EN 1504-2. It comes in a range of colours including Mid Grey, Dark Grey, Black, Green, Red, and Safety Yellow, with pre-proportioned units for easy mixing.

How long does installation typically take for a Cold Melt® system?

Installation is efficient, with priming taking 30-60 minutes to dry, membrane curing in 6-36 hours, and full system readiness for foot traffic in 24 hours at 20°C. The DPM Primer can further accelerate projects on damp/wet concrete substrates times vary by site conditions.

Is Cold Melt® compatible with different types of insulation?

Yes, it's suitable for use with various insulation materials in inverted or protected warm roof setups. Contact our team for guidance on integration to ensure thermal performance and avoid settlement issues, as per our Proteus Maintenance Guide.

What warranty options are available for Cold Melt® installations?

When installed by approved contractors and maintained according to our guidelines, Cold Melt® systems are backed by comprehensive guarantees tailored to the project. The BBA certification confirms durability for the design life of the roof in protected applications.